As well as housing a chemist and photographer’s, the new corner building will also be home to a working soda plant that will produce flavoured aerated waters for our visitors to sample.

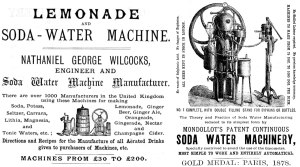

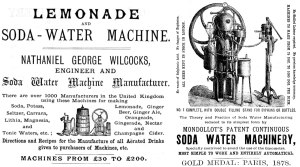

Advert for a small soda water machine of the type that chemists used.

In the 19th century soda water enjoyed massive popularity, particularly after the 1870’s when a bewildering variety of more reliable bottle closures were patented, as safer alternatives to corks (which were usually forced out by the pressure of the gas from the soda water). This fashion had a number of drivers. Along with the obvious attraction of how the fizzy drinks tasted, they was a real need for a safe and reliable, non-alcoholic drinks when away from home, when many areas still did not yet have clean, piped drinking water. The aerated drinks were also presumed to share the same health benefits as non-artificial ‘mineral waters’, which had enjoyed such popularity from early Georgian times at Bath, Leamington, Harrogate and many other spas. It is because of the guise that they were somehow healthy, that chemists became one of the main manufacturers of aerated waters.

Initial attempts at manufacturing carbonated water reportedly began in the 16th century with the experiments of Mr Thurneisser in 1560. However, the first ‘carbonation’ patent wasn’t granted until 1810, to the American partnership Simmons and Rundell. Other patents for aeration pumps were soon developed. One of the earliest was made by the Englishman Joseph Matthews in New York City in 1832. It basically consisted of a cast iron box lined with lead, in which carbonic acid gas was formed by reacting sulphuric acid with marble dust. The gas was then passed through water and agitated by hand to create soda water, after which is was mixed with salts to mimic the naturally occurring spa mineral waters. Reputedly the enterprising Matthews made twenty five million gallons of his soda water using marble off-cuts from the construction of St Patrick’s Cathedral in New York!

Our Bradford engine that is being restored so that it can power our soda pump.

Other pumps in both Britain and America used the more commercial viable ‘whiting’ or chalk dust instead of marble chips. Both large plants for high volume production and smaller versions for individual enterprises were available to order from catalogues, such as Bratby and Hinchliffes (an 1884 copy of which is in our collections). The smaller pumps, driven either by hand or by electric or gas motors, were intended for use by businesses like our Chemist, as part of a wider operation. Companies like Barnett and Forsters even sent pumps to the colonies. It would be fair to say that nearly every town in the British Empire contained a soda machine.

The soda pump that we have in our collections, which we are planning to restore, was donated in 1976 by a small family business called Innes, which operated out of Windermere Terrace in North Shields. To drive it we have recently collected a little Bradford gas engine, which is about the right scale for the size of operation that a chemist like ours would run. It has recently been sent away to experts to be returned to working condition.

In February members of the project team visited a Victorian soda plant formerly from the factory of J. B. Bowler, which had been moved and set up to its originally operational scale and layout (including the tank, pump, bottlers etc.), at the Museum of Bath at Work. While this set up was clearly too big for us to attempt to replicate, it did give us an excellent understanding of how aerated water was actually manufactured and packaged.

It also provided us with a good idea of what a ‘flavour laboratory’ may have looked like. A flavour laboratory was where the pre-made syrups would have been either stored or where new flavours were created. Pre-made syrups could be bought from wholesalers; for example in 1898 Barnett and Forster catalogue flavours include Lemon, ‘Kola’ and Ginger Beer. However, like the patent cures that were produced by chemist, every soda manufacturer appeared to have had their own recipes. These often had exotic names or alluded to have herbal or curative properties. Indeed, in an 1892 Mineral Waters Maker’s Manual, recipes are included for consumptive cough mixture, scented ointment for pimples and cattle medicine. This connection to the mixology of the chemists was also apparent at Bowler’s lab; the concentrated syrups were held in Carboys and salts measured with pharmaceutical scales. It is clear why chemists became one of the biggest outlets for soda waters.

J Bowler’s ‘flavour laboratory’ recreated at the Museum of Bath at Work.